Gladfield “Wood-Grain” Oaked Baltic Porter

Batch Size

30L Kettle Full; ~20L (in fermenter)

Ingredients

Malts

- 4.70kg Gladfield Ale Malt (67.6%)

- 1.00kg Gladfield Aurora Malt (13.5%)

- 0.55kg Gladfield Light Crystal Malt (7.4%)

- 0.55kg Gladfield Flaked Barley (7.4%)

- 0.2kg Gladfield Light Chocolate (2.7%)

- 0.1kg Gladfield Eclipse Wheat (1.4%)

Hops

- 60min – 10g Pacific Jade 12.7% (12 IBU)

- 30min – 50g Czech Saaz 3.2% aa (10 IBU)

Yeast

Lallemand BRY-97 West Coast Ale Yeast (2 Packets)

Wood

50g American Oak cubes - Medium Toasted (or you can toast your own?)

Yeast

Lallemand Verdant New England Ale Yeast (2 Packets)

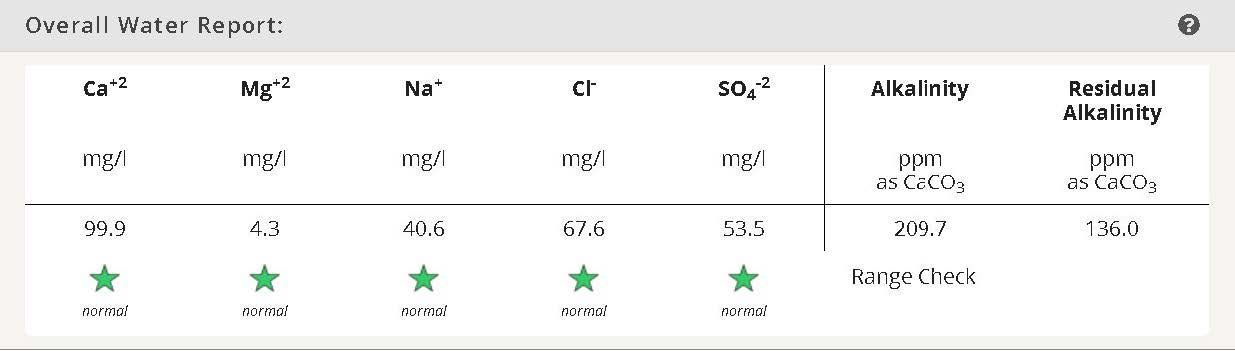

Mash Additions:

4.00g Calcium Chloride

2.00g Calcium Sulfate

4.00g Sodium Bicarbonate

6.00g Calcium Carbonate

1.00g Magnesium Sulfate

3-4mL 80% Lactic Acid (for pH Adjustment - requires pH Meter)

Brewing Process

- Heat Strike Water to achieve Mash Temp of 66°C (~6°C above strike).

- Add minerals to Strike or Foundation water.

- Begin mashing in. Measure the mash pH (once all the grain is added) to achieve 5.2-5.5 (adjust with 1 mL additions of 88% lactic acid, if required).

- Mash at 66°C for 60 mins. Confirm no residual starches remain.

- Batch sparge with 78°C water until kettle volume is achieved (or stop runoff when the last runnings drop below 1.010 and pH rises above 5.75).

- Boil for 60 minutes adding hops and kettle finings at indicated times.

- At End Of Boil, whirlpool while chilling (immersion style) or for 10 mins, stand 15 mins or until chilled to pitching temperature.

- Transfer to fermenter at 18°C, oxygenating wort (inline or via aeration in fermenter).

- Rehydrate and pitch yeast as per manufacturer's recommendations. Ferment at 18°C for the first 3-4 days.

- Raise the fermentation temperature to 19°C on day 5. When Specific Gravity points (1.5-2.0Po) from the predicted Final Gravity(FG), cap the fermentation. This is best achieved through use of a spunding valve set to ~7-8PSIG.

- When FG is reached (i.e. no change in gravity after 48hrs; no gas release from the spunding valve) raise the fermentation set point to 20°C for at least 48hrs to diacetyl rest.

- 48-72hrs after the VDK rest (i.e. Taste No Diacetyl), Crash to 6-8°C.

- Dump the bulk of the yeast cake or rack the beer into a CO2 purged secondary containing the oak cubes.

- Oak Toasting, Charring, and Aging:

Toasting your Oak: Place the cubes in a clean stainless steel roasting tray, and bake at 165°C for 30-60mins depending on the toast level you desire.

Charring your Oak: Char a portion (~50% of the total cubes) using a propane torch. Lightly burn this portion of cubes, being careful not to over char it. Keep in mind the average oak barrel only burns for between 5 – 25 seconds. Only charring half will also protect against over-charring.

Aging: You can simply add your freshly Toasted and Charred cubes to your fermenter/ secondary vessel and condition on the oak at 6-8°C. If the secondary is pressurizable, another option is to “speed age” the beer by cycling the beer for several days to weeks at both chilled (4-8°C) and ambient (~18-20°C) temperatures. This attempts to replicate the seasonal variation oak barrels experience.

- Taste the beer on a weekly basis until the desired level of Oak character is achieved.

- Keg or bottle condition - your choice?. Aim for 2.45-2.6 volumes of CO2.