Gladfield Double IPA

Batch Size

30L Kettle Full; ~20L (in fermenter)

Ingredients

Malts

- 4.1kg Gladfield American Ale Malt (51.8%)

- 2.9kg Gladfield Pilsner Malt (36.6%)

- 0.4kg Gladfield Munich Malt (5.1%)

- 0.2kg Gladfield Chit Malt (2.5%)

- 0.32kg Dextrose (Corn Sugar) (4%)

Hops

- FWH- 10g Pacific Jade 12.7% (14.8 IBU)

- 60min– 10g Mosaic 12.8% (12.8 IBU)

- 10g Columbus 15% (15 IBU)

- 10min– 15g Mosaic 12.8% (7.8 IBU)

- 10g Columbus 15% (6.1 IBU)

- 10g Nelson Sauvin 11.8% (4.8 IBU)

- Whirlpool 25g Mosaic 12.8% (6.1IBU)

- 20g Columbus 15% (5.8 IBU)

- 15g Nelson Sauvin 15% (2.9 IBU)

Dry Hopping

- DH#1 (Day 4): 110g Mosaic, 60g Columbus

- DH#2 (Day 5): 75g Nelson Sauvin, 50g Columbus,

- DH#2 (Day 6): 50g Nelson Sauvin, 100g Mosaic,

DH rate= ~22g/L

Yeast

Lallemand BRY-97 West Coast Ale Yeast (1 Packet)

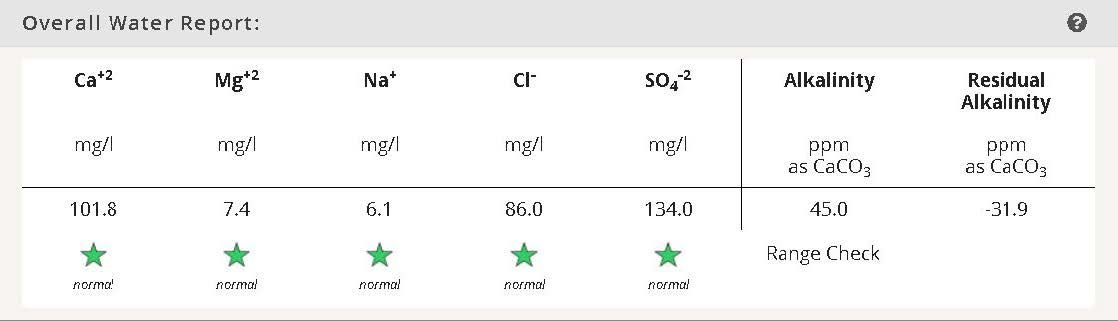

Mash Additions:

4.00g Calcium Chloride

7.00g Calcium Sulfate

1.5g Magnesium Sulfate

4-5mL 80% Lactic Acid (for pH Adjustment - requires pH Meter)

Brewing Process

- Heat Strike Water to achieve Mash Temp of 67°C (~6°C above strike).

- Add minerals to Strike or Foundation water.

- Begin mashing in. Measure the mash pH (once all the grain is added) to achieve 5.2-5.5 (adjust with 1 mL additions of 88% lactic acid, if required).

- Mash at 67°C for 45 mins. Confirm no residual starches remain.

- Batch sparge with 78°C water until kettle volume is achieved (or stop runoff when the last runnings drop below 1.010 and pH rises above 5.75).

- Boil for 60 minutes adding hops and kettle finings at indicated times.

- At End Of Boil, whirlpool while chilling (immersion style) or for 10 mins, stand 15 mins or until chilled to pitching temperature.

- Transfer to fermenter at 18-20°C, oxygenating wort (inline or via aeration in fermenter).

- Rehydrate and pitch yeast as per manufacturer's recommendations. Ferment at 18°C for the first 3-4 days.

- Begin dry hopping on day 3. Aim to add the final dry hop addition at 4-6 SG points (1-1.5Po) from the predicted Final Gravity. Once added, cap the fermentation (spunding valves are great for this), raise the fermentation set point to 22°C for at least 48hrs to diacetyl rest.

Fining/ Filtering?...

- 48-72hrs after FG is reached (i.e. Taste No Diacetyl), Crash to 5-6°C.

- Add preferred finings (Klarsol, Gelatine, etc.).

- Crash cool to 0-1°C and wait for the beer to clear naturally or filter as required.

- Keg or bottle condition - your choice? Aim for 2.55-2.65 volumes of CO2.