Gladfield and Lallemand "Extra Crisp IPA"

Batch Size

35L Brewzilla or G30 Grainfather

29L Kettle Full; ~23L (in fermenter)

Ingredients

Extra Crisp IPA

(Cold IPA with malted maize and Lalbrew NovaLager yeast)

Malt

- 5 kg Gladfield Lager Light (76%)

- 0.6 kg Gladfield Wheat Malt (9.5%)

- 0.6 kg Gladfield Malted Maize (9.5%)

- 0.15 kg Gladfield Sour Grapes (2%)

- 0.2 kg Dextrose (3%)

(6.55 kg Total Malt/Sugar)

Yeast (2 Options)

1) 1x 11g packets Lallemand NovaLager Yeast

Or…

2) 2x 11g packets Lallemand Diamond Lager Yeast

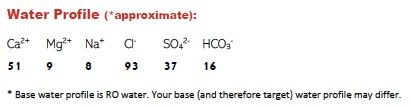

Mash Additions:

- 4.00g Calcium Chloride

- 2.00g Magnesium Sulfate

- + 2mL 80% Lactic Acid; following “all in”(to achieve pH of ~5.25).

Hops:

- 75min - 20g Citra; 11% aa = 24 IBU (@25% utilisation)

- 10min - 15g Riwaka; 5% aa = 3 IBU (@10% utilisation)

- 10min - 15g Citra; 11% aa = 7 IBU (@10% utilisation)

- WP - 35g Riwaka; 5% aa = 7 IBU (@10% utilisation)

- WP - 15g Citra; 11%aa = 7 IBU (@10% utilisation)

Total IBU = 48 IBU

Dry Hop: 50g Riwaka, 50g Citra, 100g Strata

Kettle + Additions:

1.5g Murphy and Son Protafloc - kettle finings

2g Murphy and Son Yeast Vit nutrient

25g Murphy and Son Super F

Brewing Process

- Heat Strike Water to achieve 65°C mash temp (~7°C above strike is typical).

- Add minerals to Strike or Foundation water.

- Mill the grains and mash at 65°C for 60 minutes.

- Ramp up to achieve the mash out temperature of 78°C. If you cannot heat your mash, aim to get your wort in kettle and begin heating early to attenuate any residual enzyme activity.

- Batch sparge with 77-78°C water, or top up as necessary, to obtain about 29 liters of wort

- Boil for 60 minutes, adding hops according to the schedule. Add Protafloc kettle finings and Yeast Vit 15 minutes before end of boil.

- At flame-out, whirlpool for 5 minutes, add whirlpool hops, then stand for 5 minutes.

- Chill the wort to below 16°C, aerate with pure oxygen or filtered air, and pitch the yeast. 1 x 11g sachets of Lalbrew NovaLager, or 2 x 11 g Lalbrew Diamond Lager yeast.

- Ferment at 15°C for 7 days, then allow free rise to 18°C for 4 days or until pass diacetyl test.

- Dry hop at 65-75% apparent attenuation (1.021-1.015)

- Ensure 7-10 PSI top pressure on the beer before crashing to 6°C. Lager the beer for a further 7-14 days.

- Chill to 0°C. Fining: Add 25g of Super F finings, leave for 48 hours to sediment

- Carbonate to about 2.65 volumes CO2

- Keg, bottle, or can as desired.

Enjoy!